Supply Chains Are Us

Supply chains are large industrial systems. They are composed of heterogeneous elements, such as ships, aircraft, trains, and trucks, but also systems of labor, information, and finance that build them and connect them together. Usually the goods flow in one direction and money flows in the opposite direction. Their physical substrates are themselves industrial products, relying on ships, trucks, cranes, fossil fuels, and electric power, tied together by skilled human operators, supervisors, managers, and other industrial roles.

The linear suggestion of “chain” is misleading — a supply chain is a network or tree structure of suppliers supporting other suppliers, referred to in some industries as “tiers.” In Intel’s supply chain, for example, the mines that supply tantalum ore to go into chips are buried deep in Tier 12.

Each supply chain is a network of physical, contractual, financial, and social relationships that take resources and time to build. Companies often consider these networks among their crown jewels and closely guard their secrets. “Once one understands what is involved in just a single overseas shipment to a consumer’s home,” writes MIT supply chain guru Yossi Sheffi in his book “The Magic Conveyor Belt,” “the question is not why the item does not make it on time but rather astonishment and wonder that such a thing can be completed in the first place.”

In their heyday, department stores created dream worlds that you would walk through and peer into the edges of supply chains as windows to an apparently better life. Today the internet does a great job of abstracting away those systems, hiding this enormous complexity behind a simple friendly interface to replace the plush showrooms.

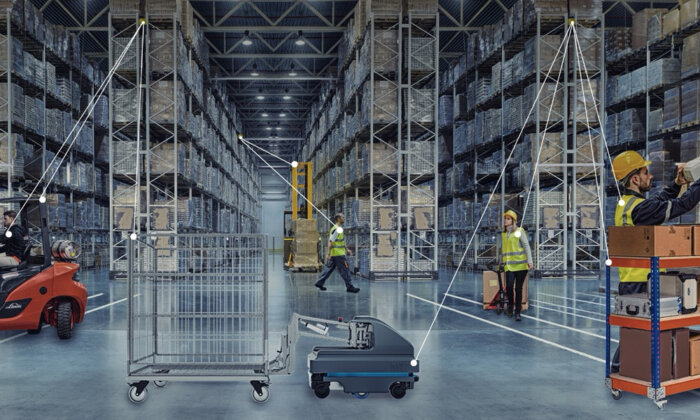

But your clicks have impacts in the human and physical worlds nonetheless. When you log on to an Amazon website, or any other e-commerce site for that matter, you are controlling a global supply chain. When you click “buy,” you initiate a series of financial, information, and human events that result in a product appearing at your door.

Few of us would likely condone every moment of every supply chain for every product we consume.

Consider any product in your home. Where was it made? (That should be written on the label somewhere.) Where were the parts made? Who put them all together? How did it get to your doorstep?

Every object embodies answers to those questions, though it’s overwhelming to think about every one. Nonetheless, it’s a worthy exercise to do every once in a while for some objects, including your food. Throw out a moldy strawberry? Imagine the vast distances (and fossil fuels) that got it to your kitchen, only to miss being edible by a few hours. And of course the journey isn’t over when you throw it in your trash. Nor is it over if you eat it; your digestion is part of the chain. Your body turns the energy stored in the strawberry into work. Our act of consumption is just a brief moment in these ever-flowing systems.

And yet that moment brings with it some level of ethical responsibility for the systems that support it. How much do you want to know about the working conditions at every stage of the supply chain? How much are you morally obligated to know, with what consequences? Few of us would likely condone every moment of every supply chain for every product we consume. Yet to fully ethically withdraw from that participation would involve a renunciation of modern life. To paraphrase the cartoon character Pogo, we have seen the supply chains and they are us.

The pandemic era taught us that disruption, the Silicon Valley term that had been prized as an emblem of bold innovation, is not acceptable when it comes to supply chains. These industrial systems are prosaic by high-tech standards — trucks, workers in brown suits, and loading docks — but essential for supporting lives in a modern industrial society.

Their goals, and the goals of the thousands of people who plan, manage, and operate them, is the opposite of disruption. Keep the goods flowing. Keep the power on. Keep the trains running. Keep everyone safe while doing it. Smoothness, reliability, and efficiency are the watchwords. Dynamism is inevitable, but disruption is the enemy.

David Mindell is Professor of Aerospace Engineering and Dibner Professor of the History of Engineering and Manufacturing at MIT and the author of several books, including “Digital Apollo” and “The New Lunar Society,” from which this article is excerpted.